Topglass

Topglass® UltimaGel

NATURAL ROOF LIGHTING-HIGH RESISTANCE AGAINST WEATHERING AND SOLAR DETERIORATION

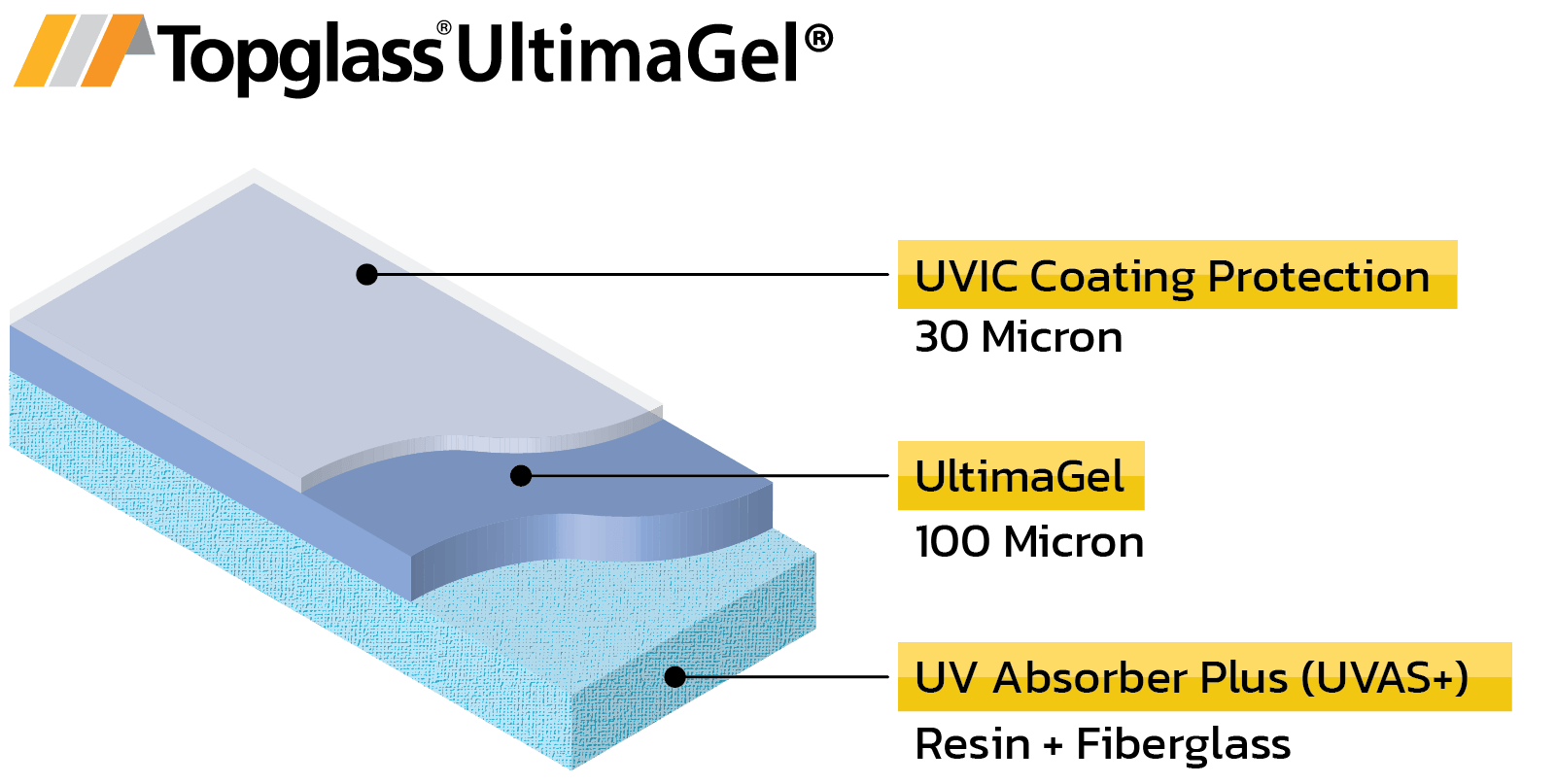

Topglass® UltimaGel is a utilizing an innovative manufacturing process developed by CHP Technology, whereby UltimaGel 100 microns Gelcoat exclusively developed for Topglass is applied to the weather surface of the sheeting. Having 100 microns thick coating offers exceptional resistance against corrosive atmospheres, and providing protection against solar deterioration that will result in glass fiber showing.

Key Benefits

– UltimaGel 100 micron gelcoated surface provides a longer life for light transmission and prevent glass showing.

– UltimaGel gel-coated surface, which is reactive thermo-set toprovide a high gloss surface.

– Topglass® UltimaGel, which is manufactured to meet the requirements of AS 4256:3.2006; resist UV degradation and yellowing much longer than is commonly experienced with general purpose grade translucent roofing products;

– Topglass® UltimaGel can be supplied in a variety of pigments and can be supplied as Topglass® UltimaGel. This innovative gelcoat additive provides excellent UVA and UVB block and offers exceptional heat and light data

Applications

–

Topglass Laboratory

1. Barcol Hardness (Barcol Impressor Model no.GYZJ.934)

2. Exposure Ultraviolet lamps M/C (Compile AS/NZS 2433)

3. Spectrophotometer (Model no. CM-3600A for measurement L,A,B)

4. Diffuse Light Tranmission M/C (AS/NZS 4257.4)

5. Impact Resistant M/C (Compile AS/NZS 4257.6)

6. QUV Accelerated Weathering Chamber UVB313 (ASTM G53)

7. Microscope Camera

Spacification

Raw Material

UVAS+ is new UV absorber resin nano technology cross-link allow more UV absorbed and less UV pass.

Top Coating

UltimaGel 100 micron gel-coated surface which is reactive thermo-set to provide a high gloss surface.

Fiber Glass

Antistatic high quality glass fibre rovings to give maximum strength during the curing and bonding process.

Bottom Coating

Release film.

Production Process

CHP Technology Cumean Hydro Peroxide Activater.

Thickness / Weight

Thickness = 1.5 mm.

Weight = 2400 gsm.

Color

Standards & Certifications

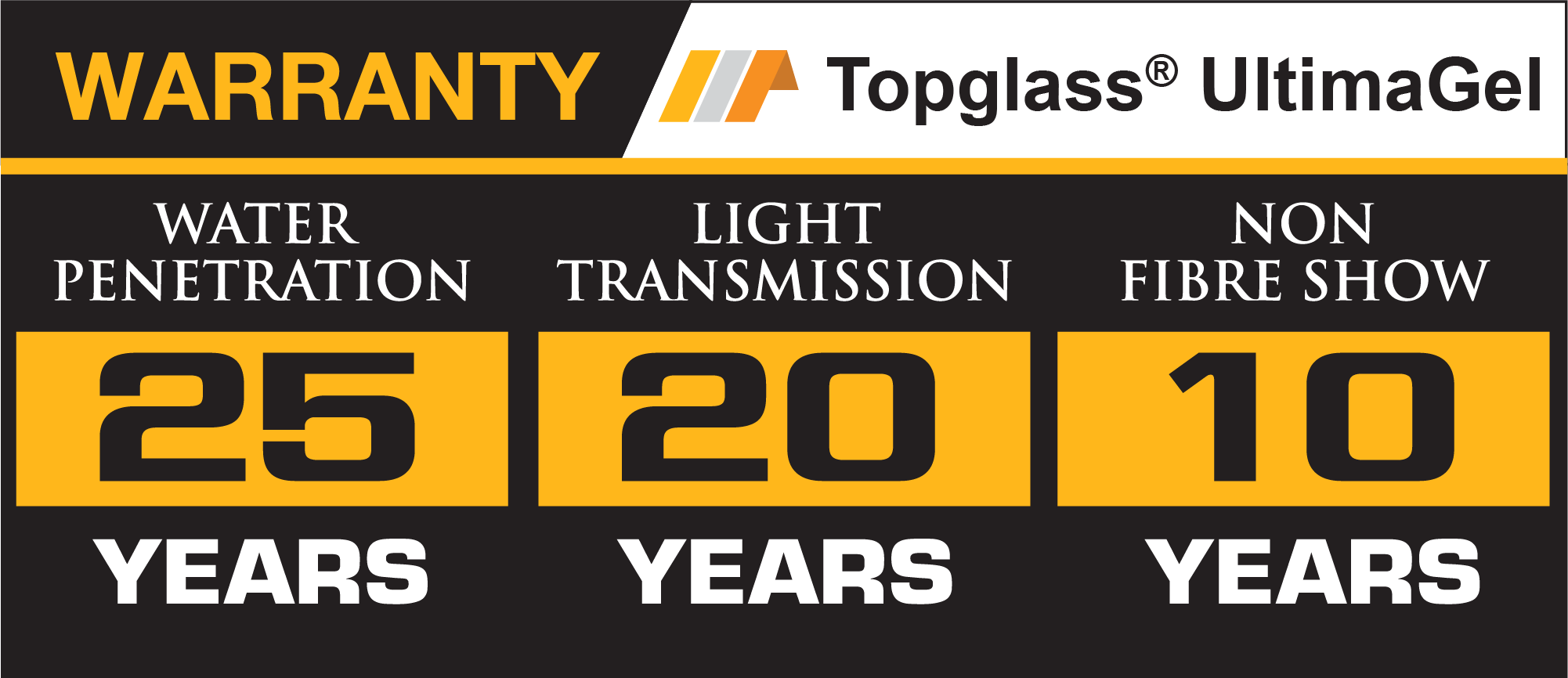

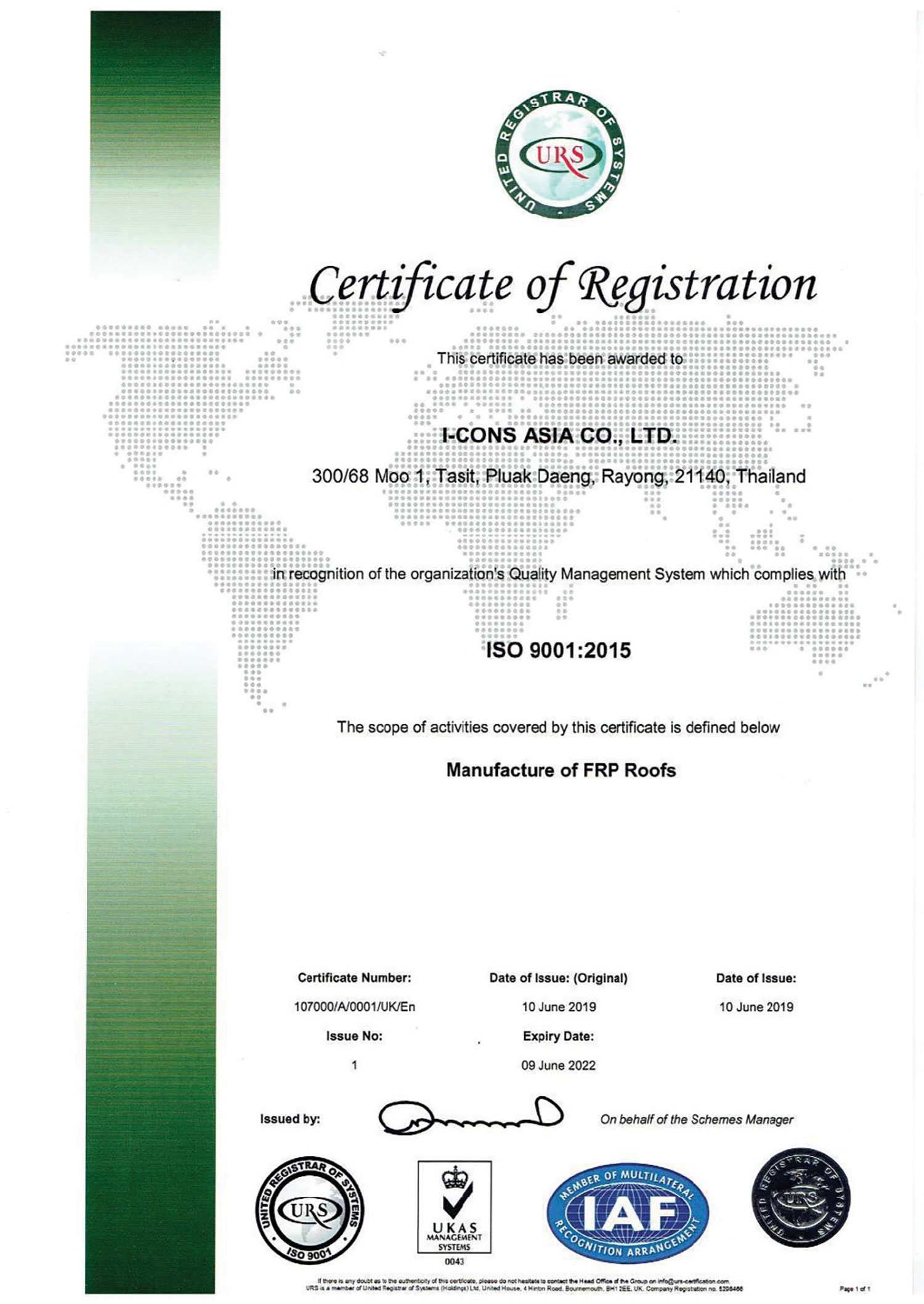

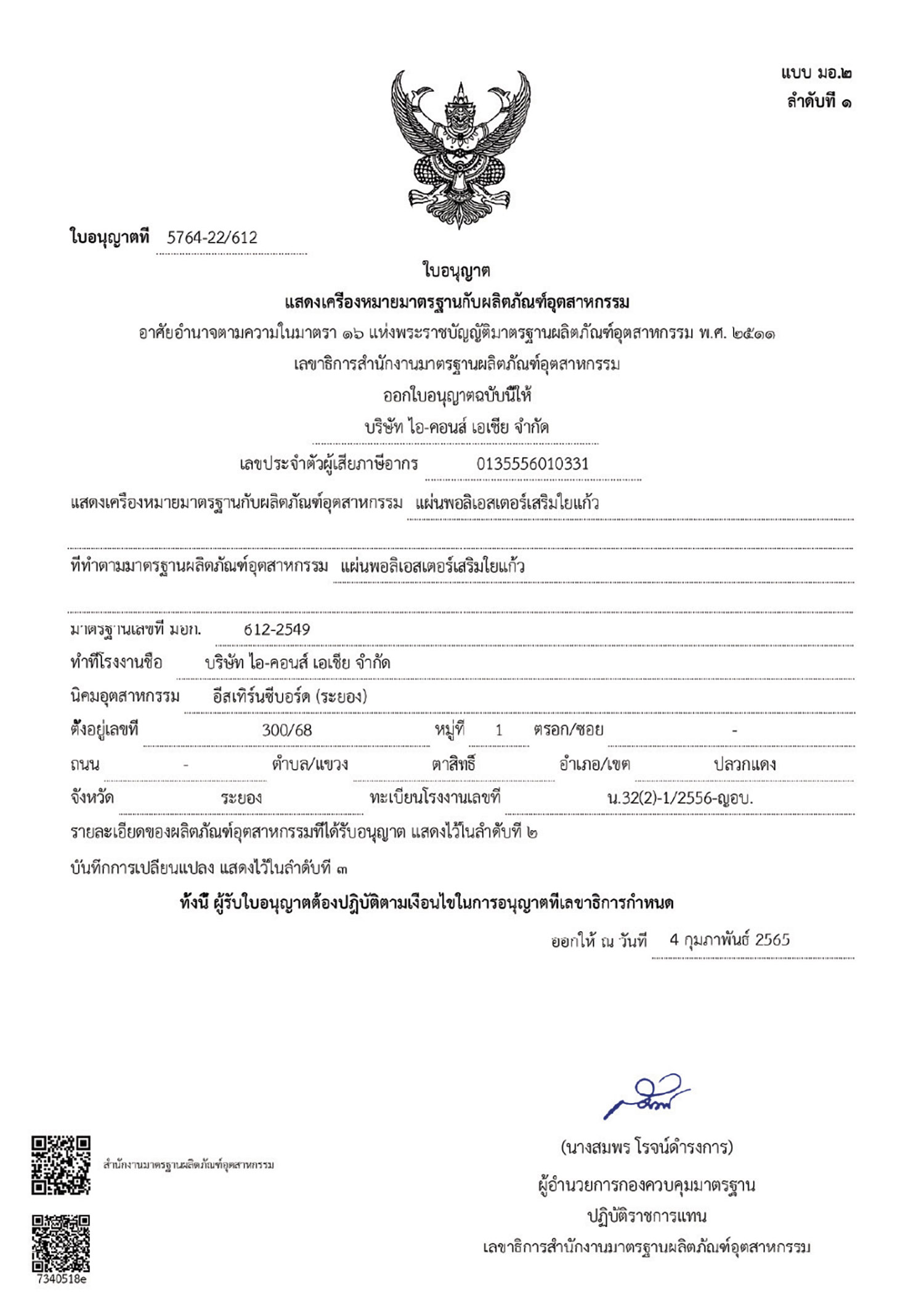

ISO 9001 : 2015

TIS 612 – 2549

AS/NZS 4256.3 : 2006

– AS/NZS 4256.3 : 2006 Plastic Roof and Wall Cladding Materials Part 3:

Glass fibre reinforced polyester (GRP) BMP No. 535535 of Australia and

From New Zealand

– TIS.612-2549 Thai Industrial Standards

– ISO 9001:2015 From URS