Topglass

Topglass® Ultima

FIBRE REINFORCED PLASTIC TRANSLUSCENT ROOFING

Key Benefits

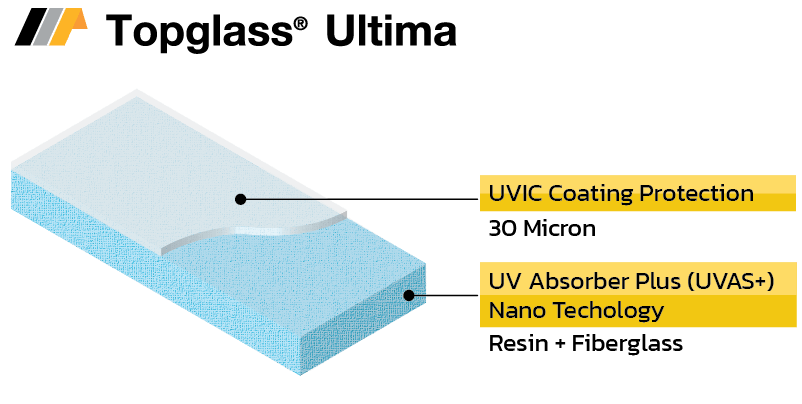

Ultraviolet Impeding Coating Plus – UVIC+

UVIC+ is tougher and thicker coating from the original UVIC feauring

an increase in thickness of 50% to 30 microns

Advantages and Benefits of these new features are

– Full UV Protection – ultimate protection of property and people

– Non-delamination of coating – full cure of the product result in permanent lamination of the UVIC+ throughout it’s life time

– A 50% increase in Surface Protection thickness – result in a tougher and longer lasting surface protection of the product and also delay in colour change

Ultraviolet Absorber Stabilizer Plus – UVIS+

UVIS+ is a new breakthrough whre it is now able to pack more UV absorber into resin through nano technology reducing the size of each absorber causing it to cross-link allowing more UV Beingabsorbed and less UV being pass through.

Advantages and Benefits of these new features are

– Higher absorption of UV – slows down changes in of product

– Increase light transmission lifespan – more light for the propety

Applications

–

Topglass Laboratory

1. Barcol Hardness (Barcol Impressor Model no.GYZJ.934)

2. Exposure Ultraviolet lamps M/C (Compile AS/NZS 2433)

3. Spectrophotometer (Model no. CM-3600A for measurement L,A,B)

4. Diffuse Light Tranmission M/C (AS/NZS 4257.4)

5. Impact Resistant M/C (Compile AS/NZS 4257.6)

6. QUV Accelerated Weathering Chamber UVB313 (ASTM G53)

7. Microscope Camera

Spacification

Raw Material

UVAS+ is new UV absorber resin nano technology cross-link allow more UV absorbed and less UV pass.

Top Coating

UVIC+ coating from the original UVIC featuring an increase in thickness of 50% to 30 microns.

Fiber Glass

Antistatic high quality glass fibre rovings to give maximum strength during the curing and bonding process.

Bottom Coating

Release film.

Production Process

CHP Technology Cumean Hydro Peroxide Activater.

Thickness / Weight

Thickness = 1.5 mm.

Weight = 2400 gsm.

Color

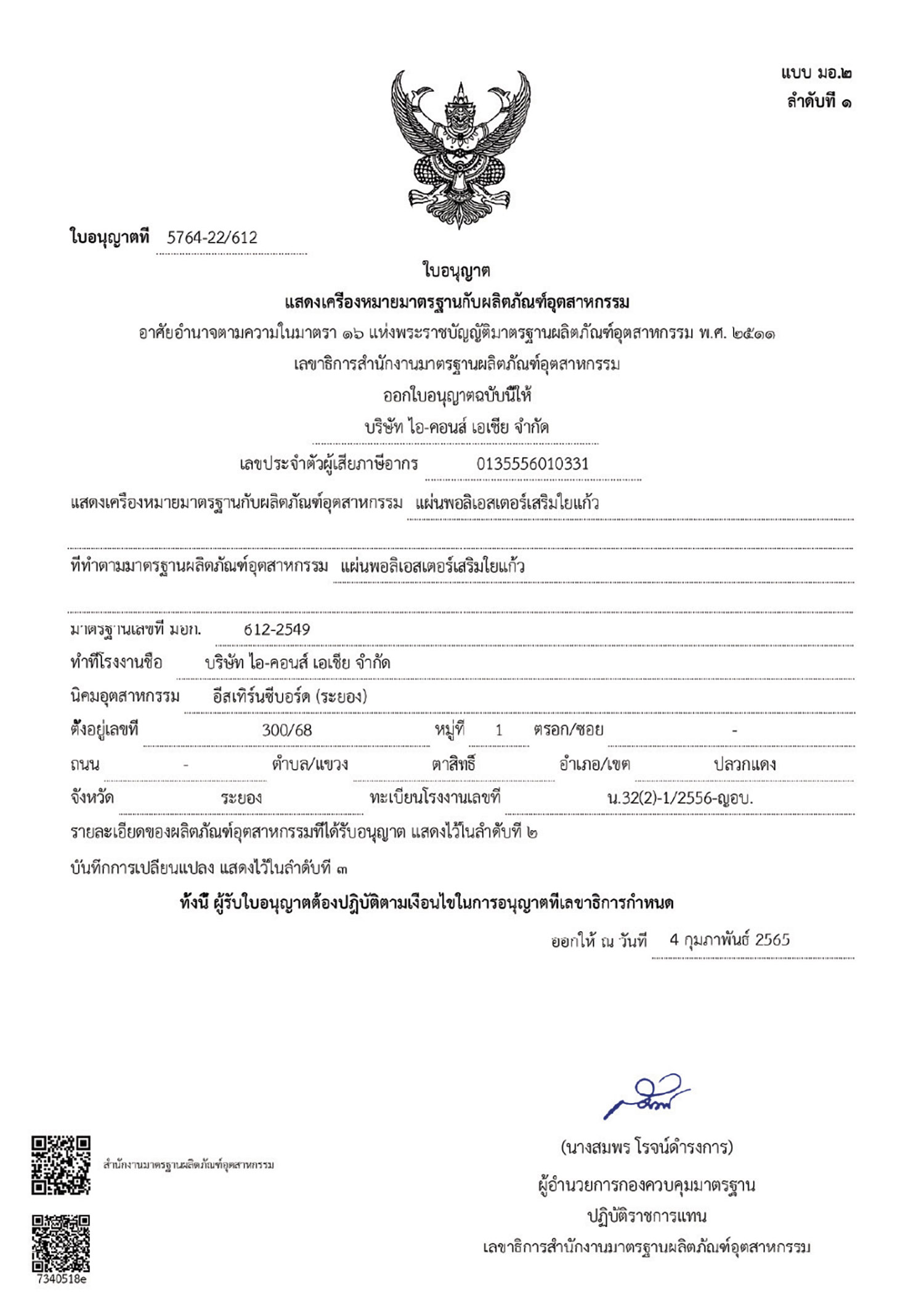

Standards & Certifications

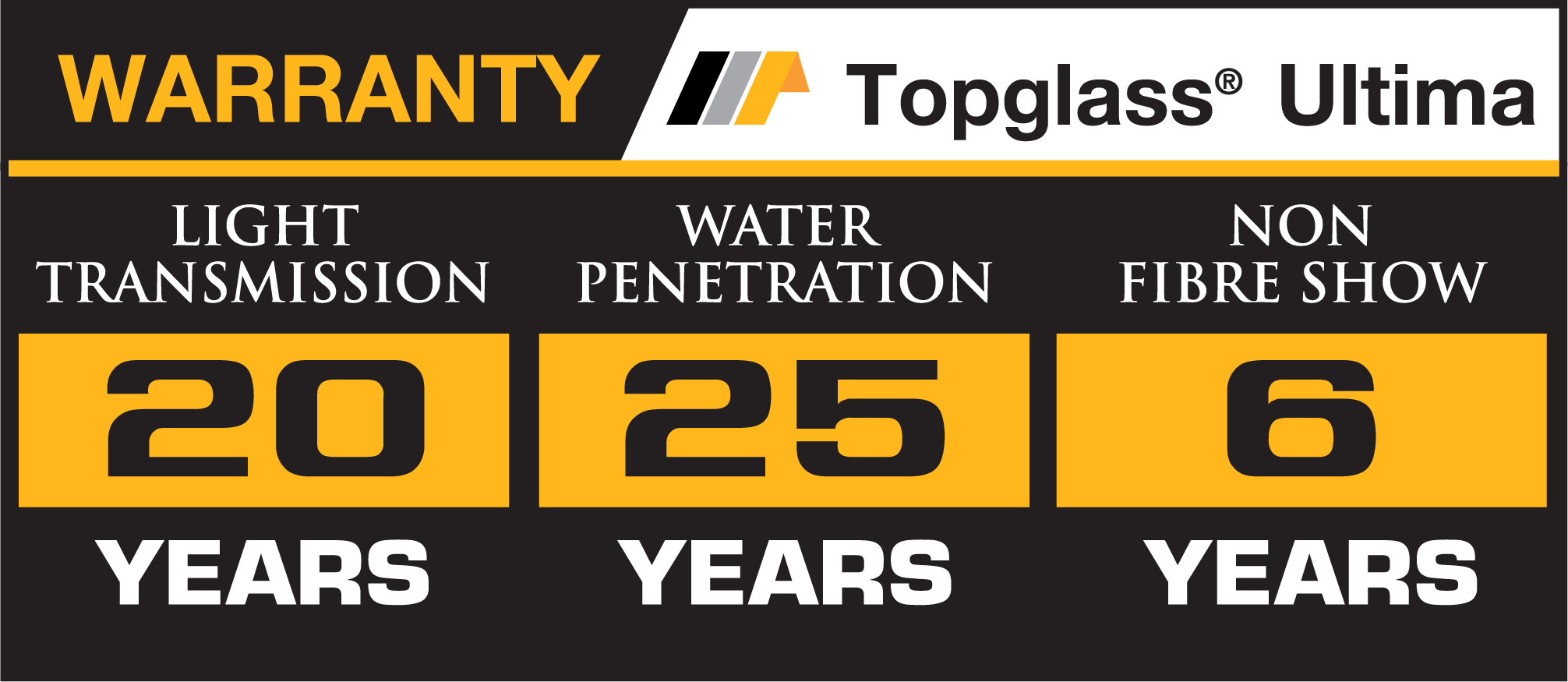

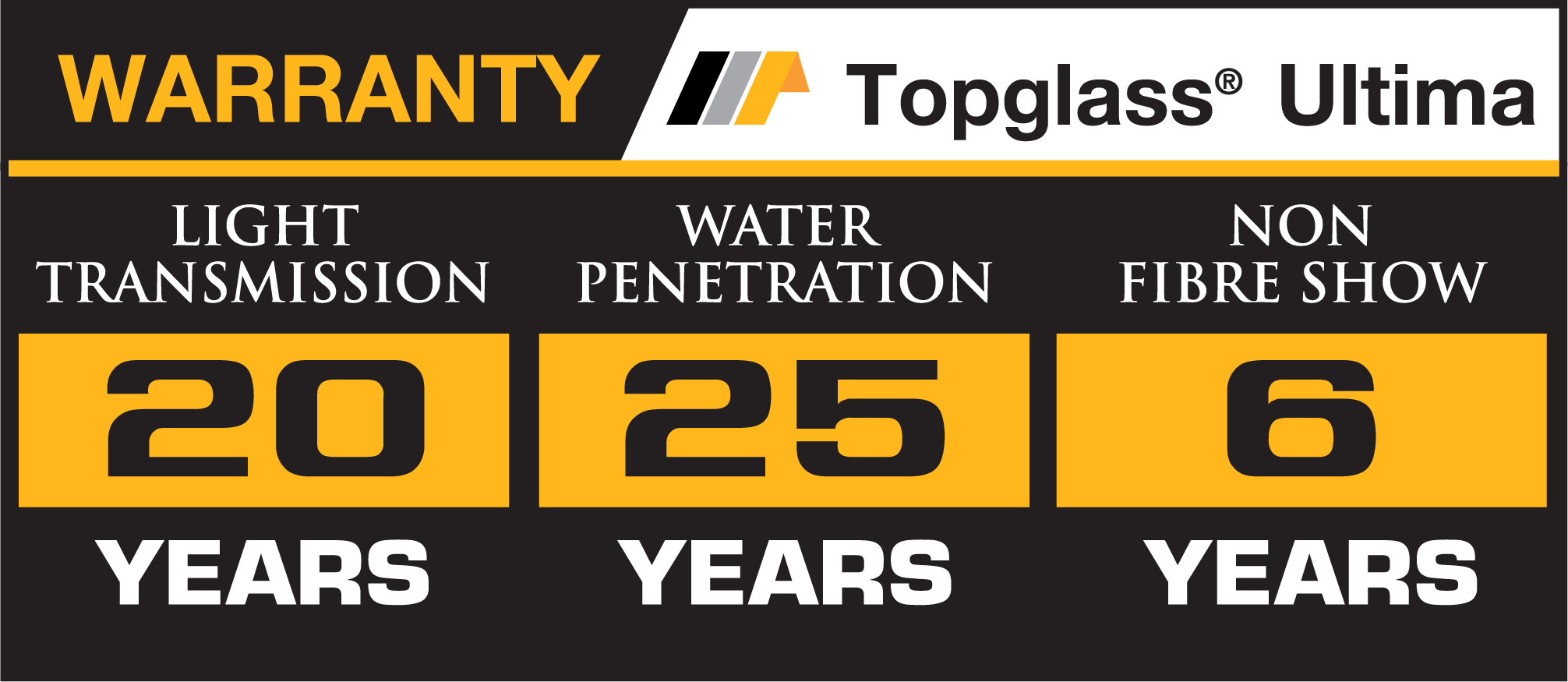

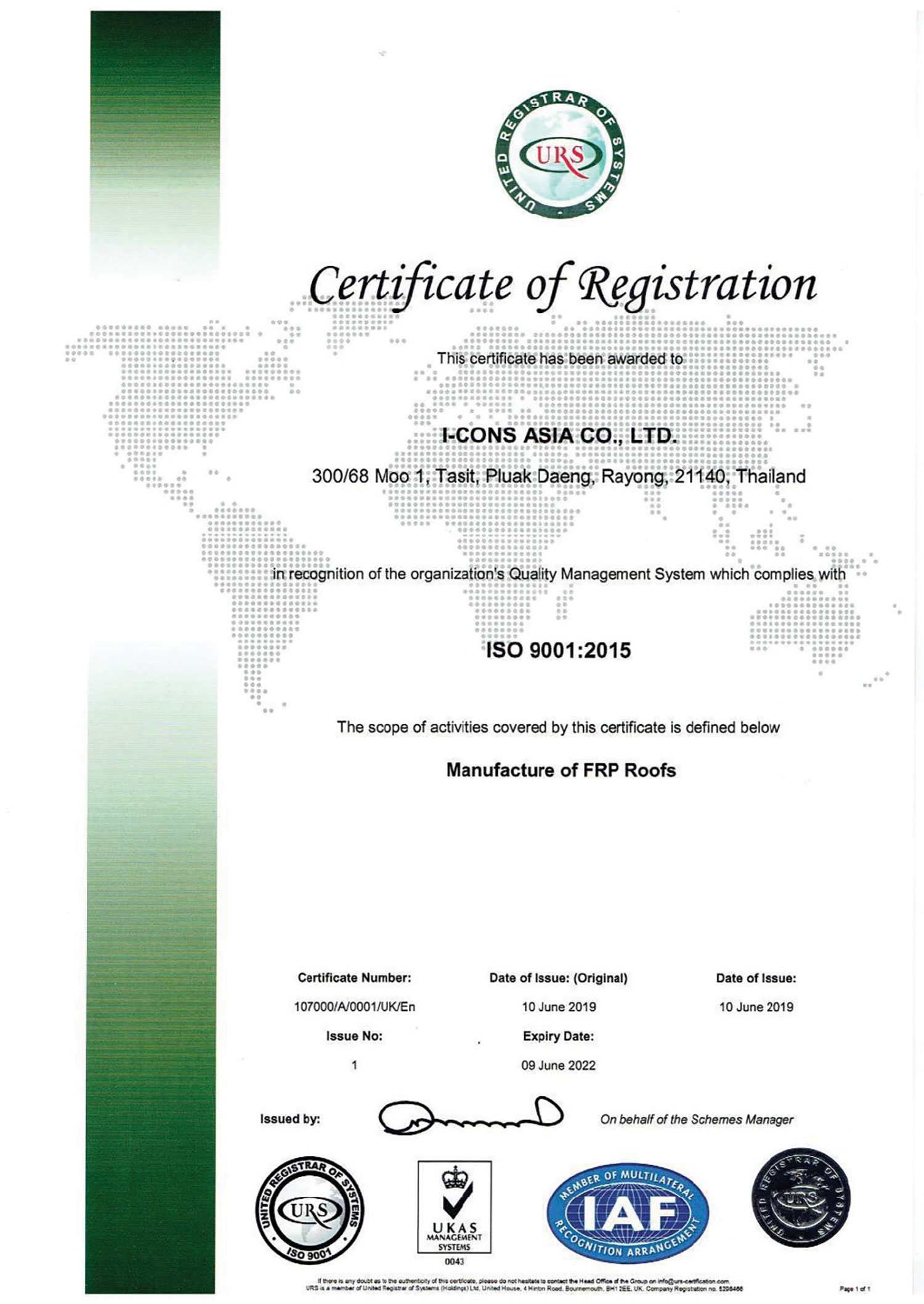

ISO 9001 : 2015

TIS 612 – 2549

AS/NZS 4256.3 : 2006

– AS/NZS 4256.3 : 2006 Plastic Roof and Wall Cladding Materials Part 3:

Glass fibre reinforced polyester (GRP) BMP No. 535535 of Australia and

From New Zealand

– TIS.612-2549 Thai Industrial Standards

– ISO 9001:2015 From URS