Topglass

Topglass® GC Ultra-Safe

HIGH IMPACT CORROSION RESISTANT GLASS REINFORCED ROOFING AND CLADDING

Where there is a possibility of FRP translucent fiberglass roofing sheets posing a danger to foot traffic on the roof or a possibility of not being able to install safety netting under the FRP translucent fiberglass roofing sheets, I-Cons Asia had jointly developed a heavy duty and high impact roof lighting system to alleviate these concerns. Aptly named Topglass GC Ultra-Safe, the product utillses a heavy duty, woven roving reinforcing system positioned within the resin matrix, thereby providing exceptional strength. This made Topglass GC Ultra-Safe trafficable after meeting the impact strength tests of

AS 4256.3 clause 11.3, AS 4040.4:1996

Key Benefits

Whilst Topglass GC Ultra-Safe is classified as heavy duty, meets the impact test of AS 4040, satisfying the reequirements of AS 4256.3, and can support foot traffic, long term degradation and or post roof installation impact damage can seriously affect the performance of the sheeting. In order to comply with the requirements of AS 1562.3:2006 Part 3 Plastic, protect the weather surface coating and provide continual structural strength, all FRP products should be protected from foot traffic, therefore a suitable proprietary aluminium walkway is always recommended

Weight/Thickness of sheeting

Topglass GC Ultra-Safe is supplied as standard weight of 3660g/m2 (2.5 mm)

Applications

– Educational facilities and Public Assembly areas where there is a danger of persons climbing onto a roof.

– Fertilizer Plants.

– Chemical and Powder-coating Plants.

– Wastewater treatment plants.

– Salt Extraction Facilities.

– Saver marine environments.

– Natural roof lighting where safety mesh is not installed.

– Wood, Pulp and Paper Plants.

Topglass Laboratory

1. Barcol Hardness (Barcol Impressor Model no.GYZJ.934)

2. Exposure Ultraviolet lamps M/C (Compile AS/NZS 2433)

3. Spectrophotometer (Model no. CM-3600A for measurement L,A,B)

4. Diffuse Light Tranmission M/C (AS/NZS 4257.4)

5. Impact Resistant M/C (Compile AS/NZS 4257.6)

6. QUV Accelerated Weathering Chamber UVB313 (ASTM G53)

7. Microscope Camera

Spacification

Raw Material

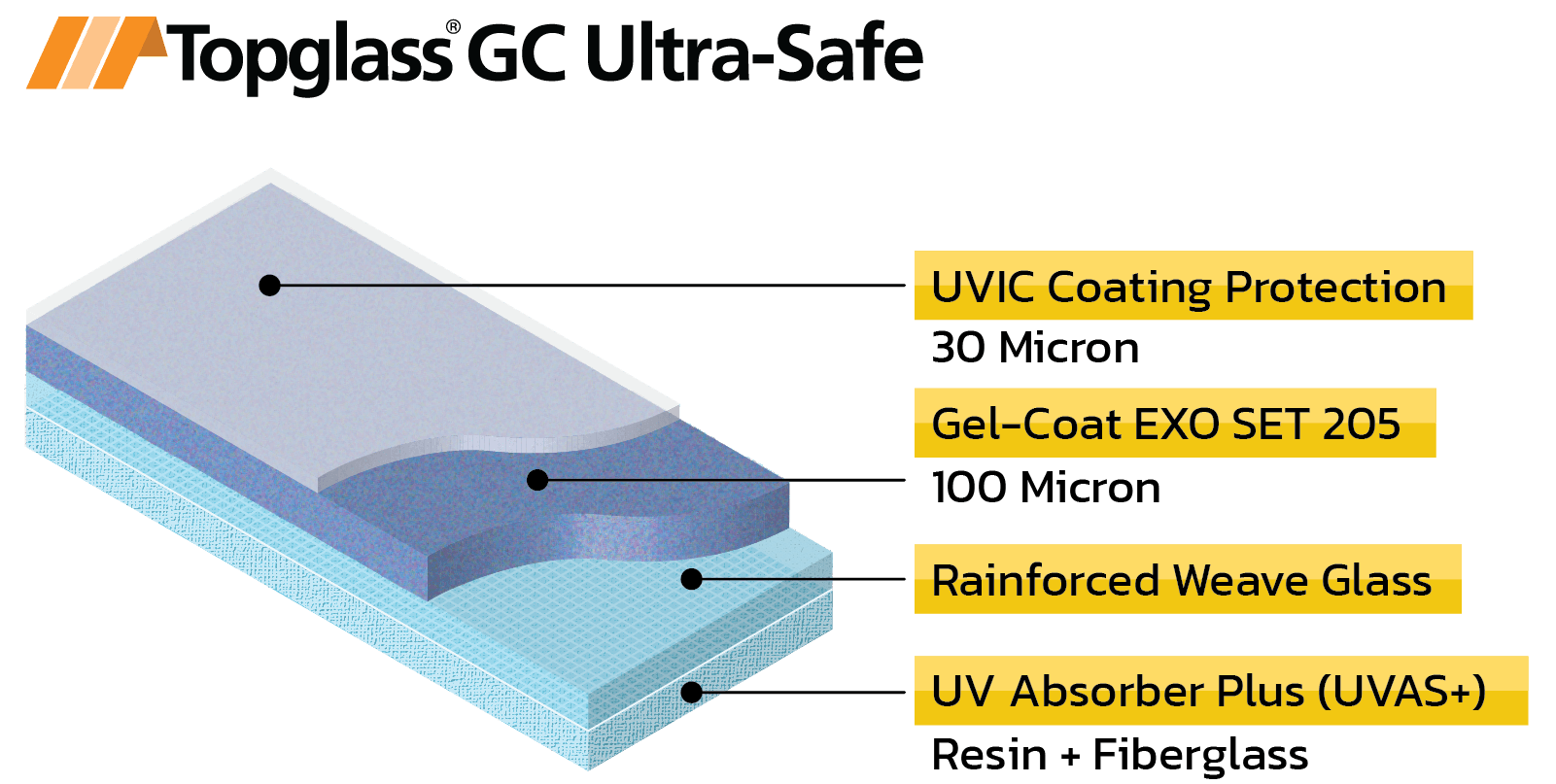

UVAS+ is new UV absorber resin nano technology cross-link allow more UV absorbed and less UV pass.

Top Coating

EXO-SET 205 SPF Hybrid Solar Protection 100 micron gel-coated surface which is reactive thermo-set to provide a high gloss surface.

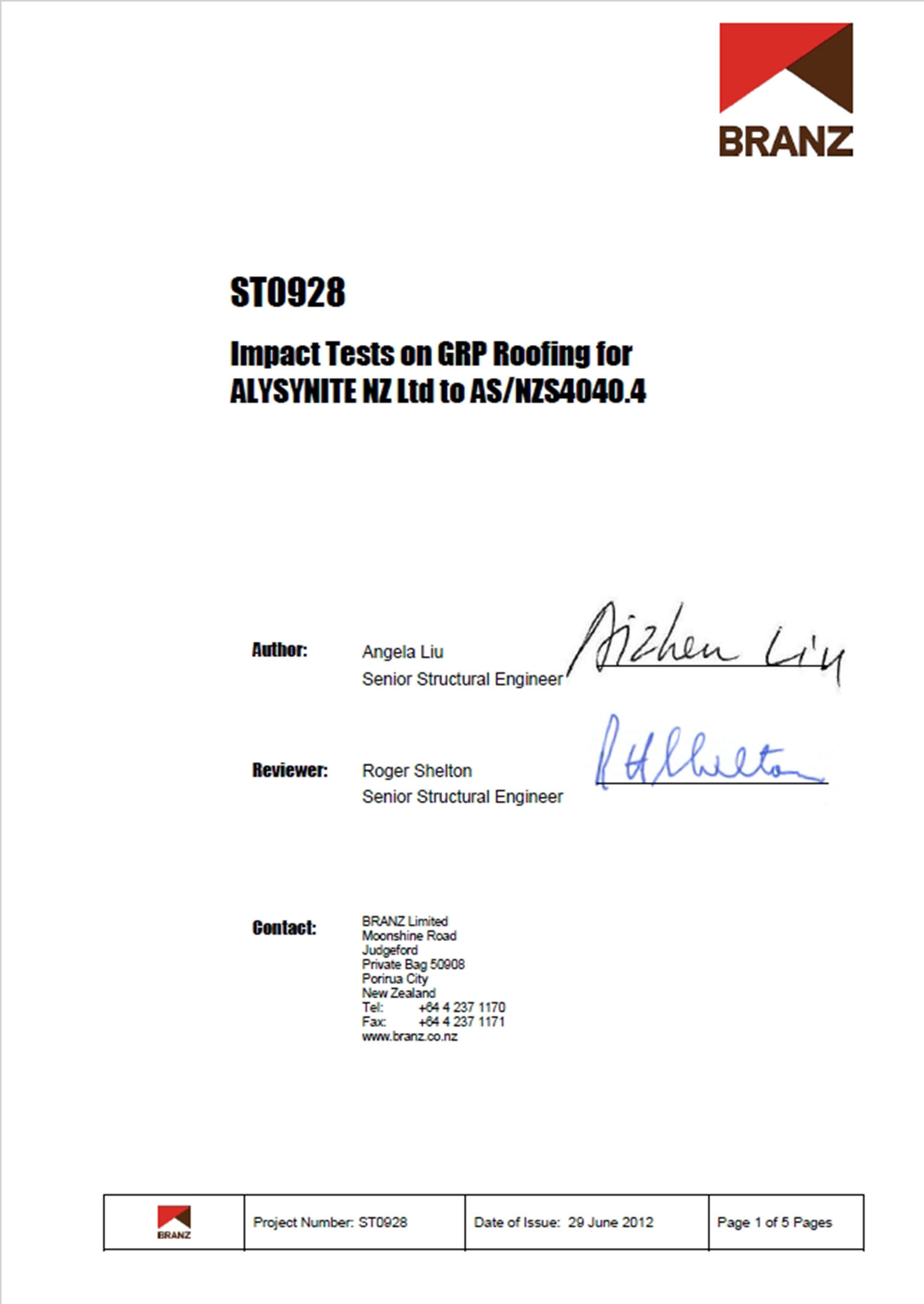

Safety Net Utilises a heavy duty, woven roving reinforcing system positioned within the resin matrix, thereby providing exceptional strength. BRANZ AUSTRALIA (AS/NZS 4040)

Fiber Glass

Antistatic high quality glass fibre rovings to give maximum strength during the curing and bonding process.

ชั้นเคลือบล่าง Bottom Coating

Release film.

Production Process

CHP Technology Cumean Hydro Peroxide Activater.

Thickness / Weight

Thickness = 1.5 mm.

Weight = 2400 gsm.

Color

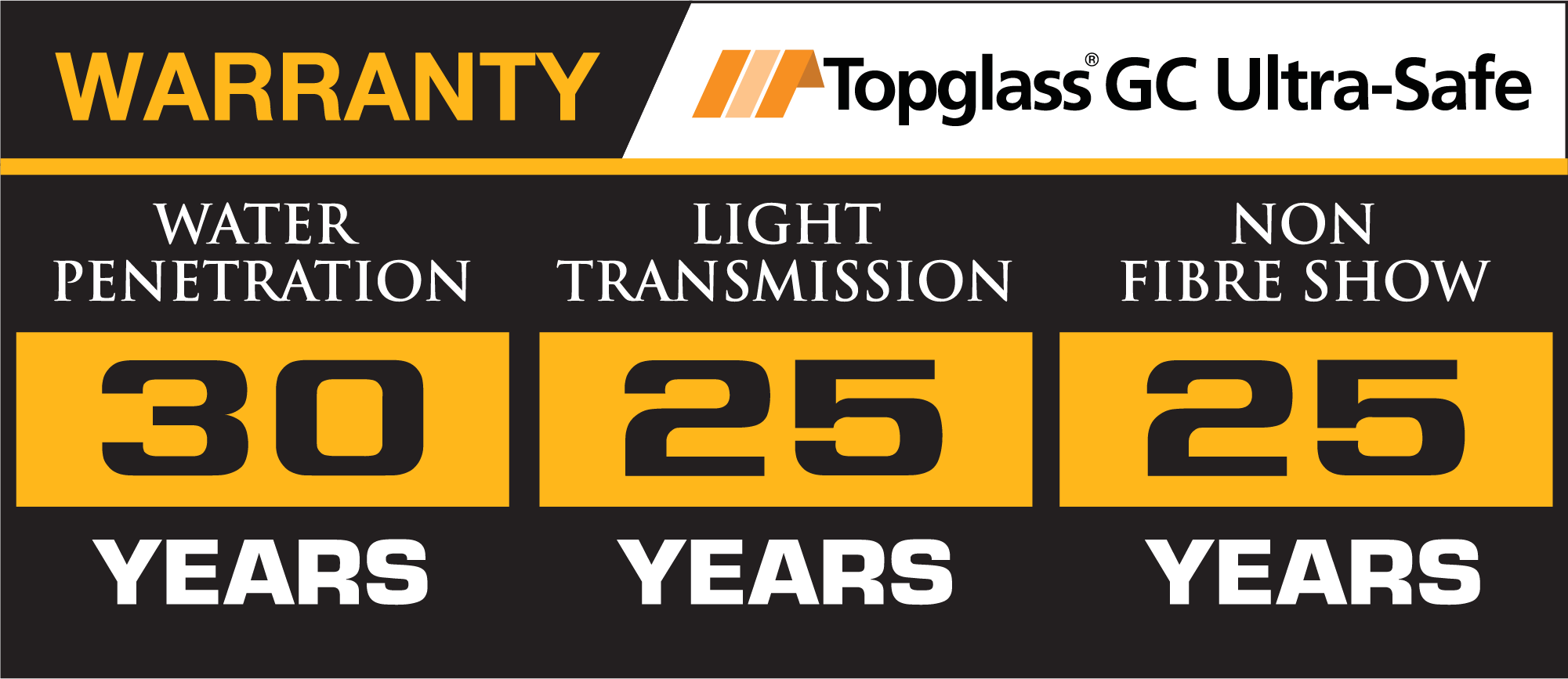

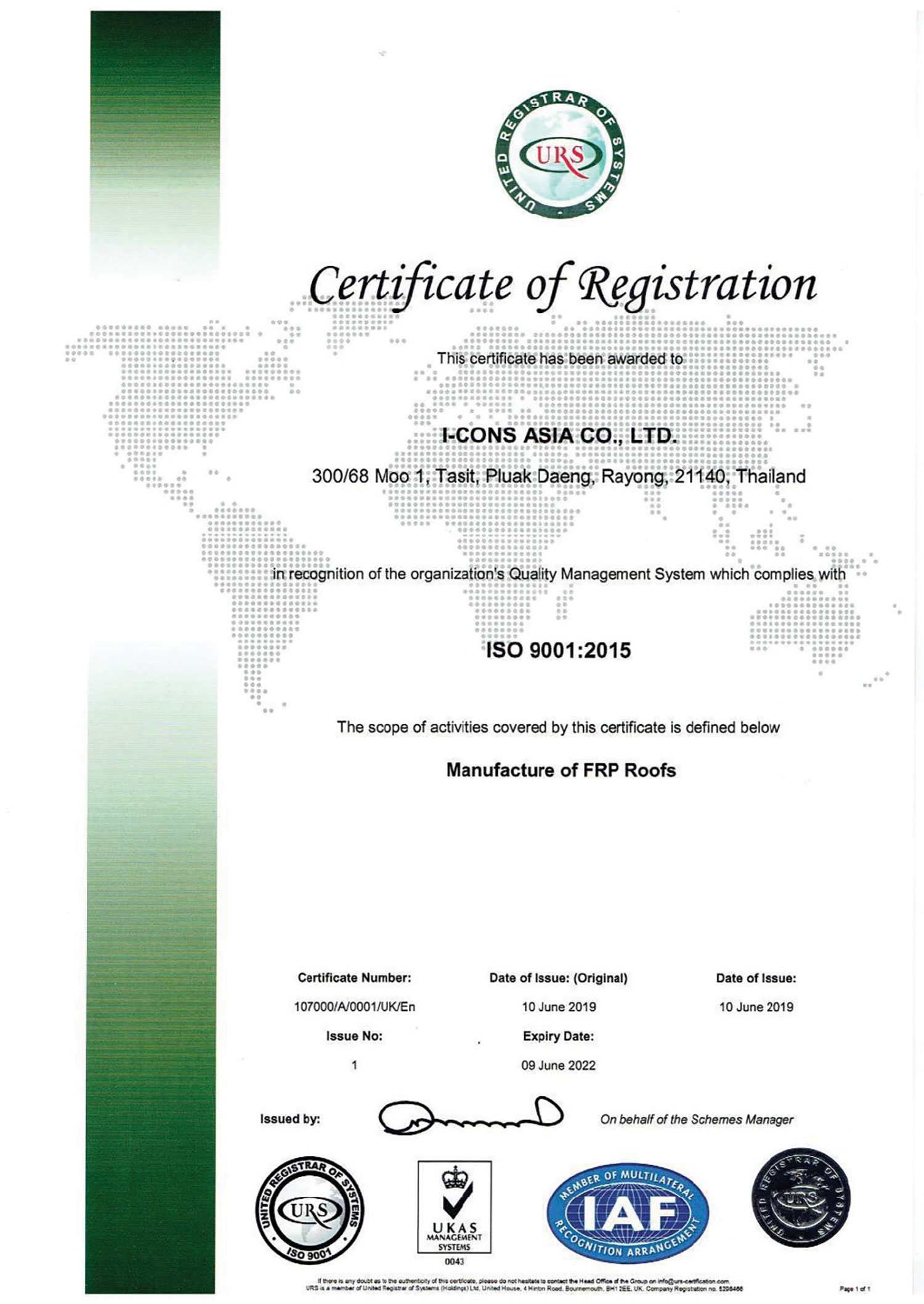

Standards & Certifications

ISO 9001 : 2015

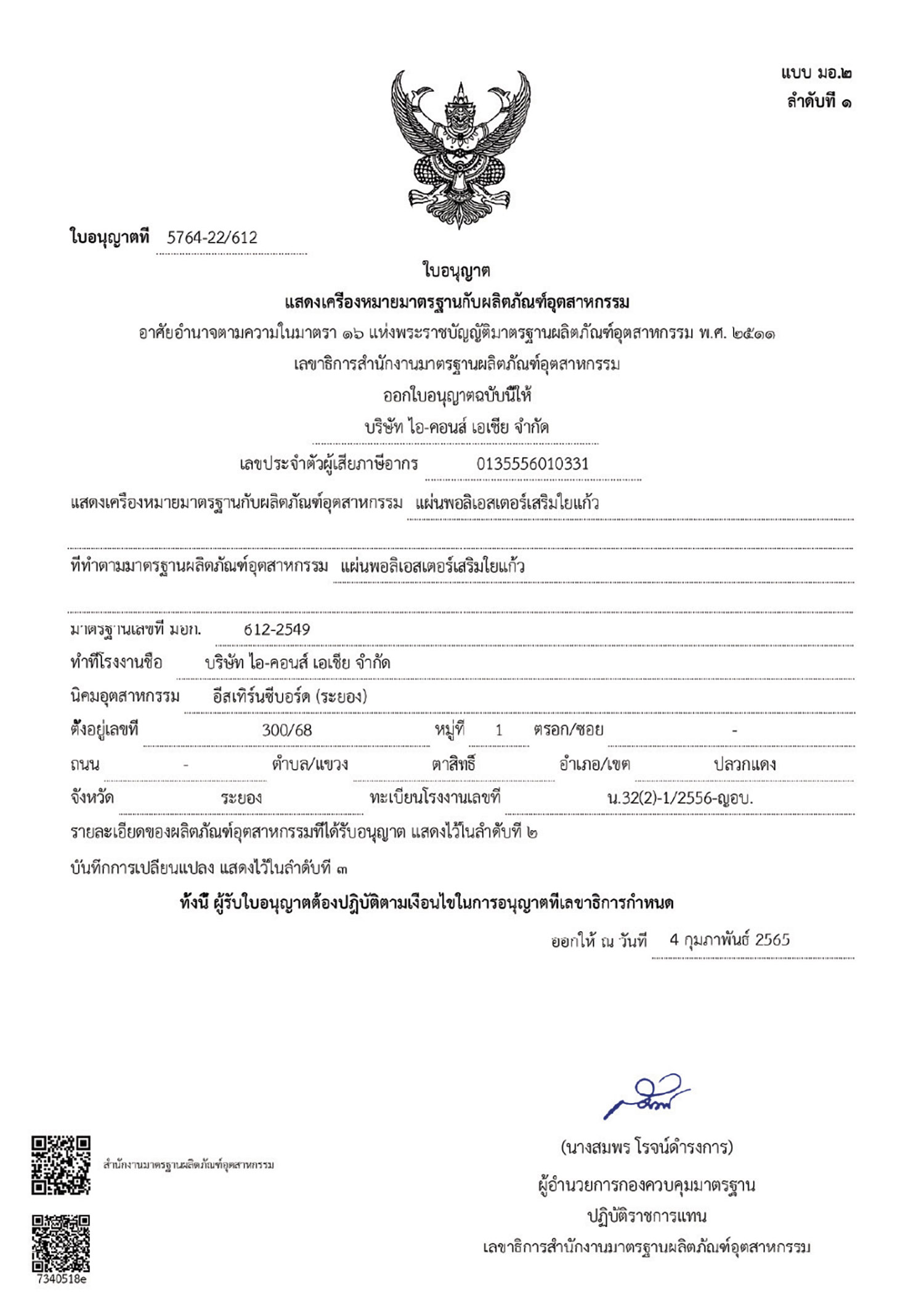

TIS 612 – 2549

AS/NZS 4256.3 : 2006

Impact Tests on GRP Roofing AS/NZS4040.4

– AS/NZS 4256.3 : 2006 Client BMP NO.535535 Plastic Roof and Wall Cladding Materials ID : 4115 จากประเทศนิวซีแลนด์

– มอก.612-2549 มาตรฐานอุตสาหกรรมจากกระทรวงอุตสาหกรรมประเทศไทย

– ISO 9001:2015 จาก URS