FIX-Plus Self-Drilling Fasteners

FIX-Plus self-drilling fasteners are manufactured in accordance to the international standard AS3566 requirements including the design, physical properties and corrosive resistance requirements for the fastening of non-ferrous metals, tiles, cement sheets, window frames, thin metal sheets, board, and etc.

FIX-Plus offers the widest range of self-drilling fasteners in Asia from Class-3 corrosion resistance requirement and from the smallest 5 gauge (3.2 mm.) to 16 gauge (6.8 mm.) in diameter and from the shortest 10 mm. to 175 mm. long fasteners.

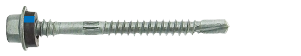

PRODUCT FEATURES

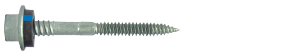

Screw Head

– Push metal sheet up to prevent leakage

– Keep position of metal sheet when lead is apply

Shank Protection

– Prevent vibration

– Prevent over tightening

Sabre Point

– Patented SABRE drilling point is the most reliable and fastest drilling point capable of up to 20 mm. thick steel

– Sharp point specially design for timber application

TrueBlue EPDM Dekseal

– Non-conductive EPDM seal exceeds AS 3566 standard requirement

– Prevents electro-galvanic corrosion compare to conductive EPDM

– High elastic high length and high anti-UV to last the lifetime of the roof

WASHER

True Blue DEKS Blue

Seal Washer

ADAPTER TO USE

Magnetic Hex

Socket #8 (5/16)

SCREW DRIVER

Screw Driver Machine

or Drilling Machine (450 Watt)

SCREW SIZE

Crest Fixing Screws

Name : Fix Plus 12-14×48 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 48 mm.

Name : Fix Plus 12-14×55 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 55 mm.

Name : Fix Plus 12-14×65 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 65 mm.

Valley Fixing Screws

Name : Fix Plus 10-16×16 HS

Gauge : 10

T.P.I. : 16

Drill Point : TRP

Length : 16 mm.

Name : Fix Plus 12-14×20 HS

Gauge : 10

T.P.I. : 14

Drill Point : TEK

Length : 20 mm.

Name : Fix Plus 15-15×20 HS

Gauge : 15

T.P.I. : 15

Drill Point : TEK

Length : 20 mm.

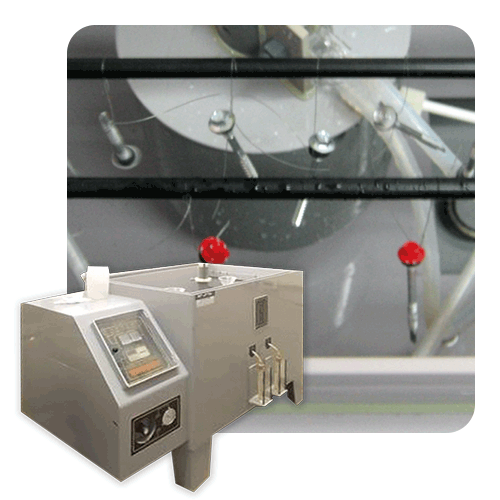

AS 3566 Class 3 Regulation

(A) AS3566 CLASS-3 ACCELERATED TESTING COMPLIANCE

1. Salt Spray Test in accordance with AS2331.3.1 – 1,000 hrs (less than 5% red rust)

2. Kesternich Test in accordance with DIN 50018 – 15 cycles (less than 5% red rust)

3. Humidity Test 100% Humidity in accordance with ASTM D2247 – 1,000 hrs (no blister size S3 or larger)

4. Ultraviolet Test in accordance with ASTM G154 – 2,000 hrs (no cracking, faking and peeling)

Salt Sprey Test

Kesternich

Ruspert Tech Corrosion Protection Coating System

Heat Treatment

Controlled heat treatment process release hydrogen preventing hydrogen embrittlement. Also well controlled hardness on both surface and core of fastener prevents all metallurgical defects.

Metallic Zinc Layer

15 microns thickness the substrate is protected from corrosion by the self-sacrificial galvanic effect of zinc.

Rust Proof Coating

10 micron of High chemical resistance top coating withstands environment versatile. Weather resistance is improved by corrugated aluminum flakes by UV reflection

WARRANTY 10 YEARS

Characterised by fall-out from adjoining severe industrial environments or where small industries lead to significant industrial fall-out. Generally includes other service buildings located near heavy industrial plants, including out-buildings of the plant itself.

FIX-Plus Self-Drilling Fasteners

FIX-Plus self-drilling fasteners are manufactured in accordance to the international standard AS3566 requirements including the design, physical properties and corrosive resistance requirements for the fastening of non-ferrous metals, tiles, cement sheets, window frames, thin metal sheets, board, and etc.

FIX-Plus offers the widest range of self-drilling fasteners in Asia from Class-3 corrosion resistance requirement and from the smallest 5 gauge (3.2 mm.) to 16 gauge (6.8 mm.) in diameter and from the shortest 10 mm. to 175 mm. long fasteners.

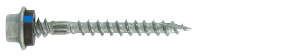

PRODUCT FEATURES

Screw Head

– Push metal sheet up to prevent leakage

– Keep position of metal sheet when lead is apply

Shank Protection

– Prevent vibration

– Prevent over tightening

Sabre Point

– Patented SABRE drilling point is the most reliable and fastest drilling point capable of up to 20 mm. thick steel

– Sharp point specially design for timber application

TrueBlue EPDM Dekseal

– Non-conductive EPDM seal exceeds AS 3566 standard requirement

– Prevents electro-galvanic corrosion compare to conductive EPDM

– High elastic high length and high anti-UV to last the lifetime of the roof

WASHER

True Blue DEKS Blue Seal Washer

ADAPTER TO USE

Magnetic Hex Socket #8 (5/16)

SCREW DRIVER

Screw Driver Machine or Drilling Machine (450 Watt)

SCREW SIZE

Crest Fixing Screws

Name : Fix Green TS0.5 HHS

Gauge : 10

T.P.I. : 24

Drill Point : Needle Point

Length : 45 mm.

Name : Fix Green STL-1 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 46 mm.

Name : Fix Green 12-14×48 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 48 mm.

Name : Fix Green12-14×55 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 55 mm.

Name : Fix Green 12-14×65 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 65 mm.

Name : Fix Green 12-14×75 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 75 mm.

Name : Fix Green 12-14×85 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 85 mm.

Name : Fix Green 12-11×50 HHS

Gauge : 12

T.P.I. : 11

Drill Point : T17

Length : 50 mm.

Name : Fix Green 12-11×65 HHS

Gauge : 12

T.P.I. : 11

Drill Point : T17

Length : 65 mm.

Valley Fixing Screws

Name : Fix Green 10-16×30 HS

Gauge : 10

T.P.I. : 16

Drill Point : TEK

Length : 30 mm.

Name : Fix Green 10-16×20 HS

Gauge : 10

T.P.I. : 16

Drill Point : TEK

Length : 20 mm.

Name : Fix Green 10-16×16 HS

Gauge : 10

T.P.I. : 16

Drill Point : TEK

Length : 16 mm.

Name : Fix Green 15-15×20 HS

Gauge : 15

T.P.I. : 15

Drill Point : TEK

Length : 20 mm.

Name : Fix Green 10-12×20 HS

Gauge : 10

T.P.I. : 12

Drill Point : TEK

Length : 20 mm.

AS 3566 Class 3 Regulation

(A) AS3566 CLASS-3 ACCELERATED TESTING COMPLIANCE

1. Salt Spray Test in accordance with AS2331.3.1 – 1,000 hrs (less than 5% red rust)

2. Kesternich Test in accordance with DIN 50018 – 15 cycles (less than 5% red rust)

3. Humidity Test 100% Humidity in accordance with ASTM D2247 – 1,000 hrs (no blister size S3 or larger)

4. Ultraviolet Test in accordance with ASTM G154 – 2,000 hrs (no cracking, faking and peeling)

Ruspert Tech Corrosion Protection Coating System

Heat Treatment

Controlled heat treatment process release hydrogen preventing hydrogen embrittlement. Also well controlled hardness on both surface and core of fastener prevents all metallurgical defects.

Metallic Zinc Layer

15 microns thickness the substrate is protected from corrosion by the self-sacrificial galvanic effect of zinc.

Rust Proof Coating

10 micron of High chemical resistance top coating withstands environment versatile. Weather resistance is improved by corrugated aluminum flakes by UV reflection

WARRANTY 5 YEARS

Characterised by fall-out from adjoining severe industrial environments or where small industries lead to significant industrial fall-out. Generally includes other service buildings located near heavy industrial plants, including out-buildings of the plant itself.