Topglass

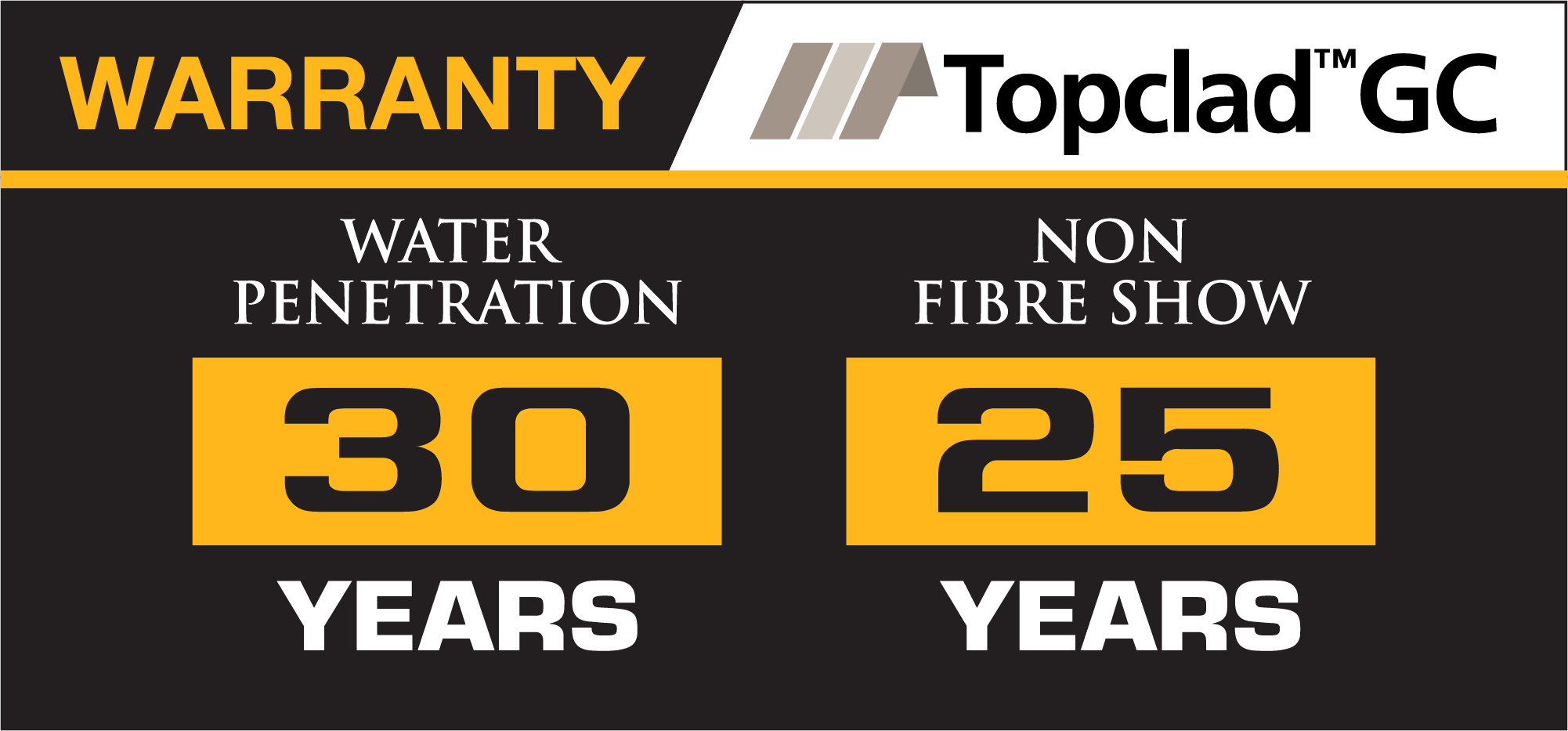

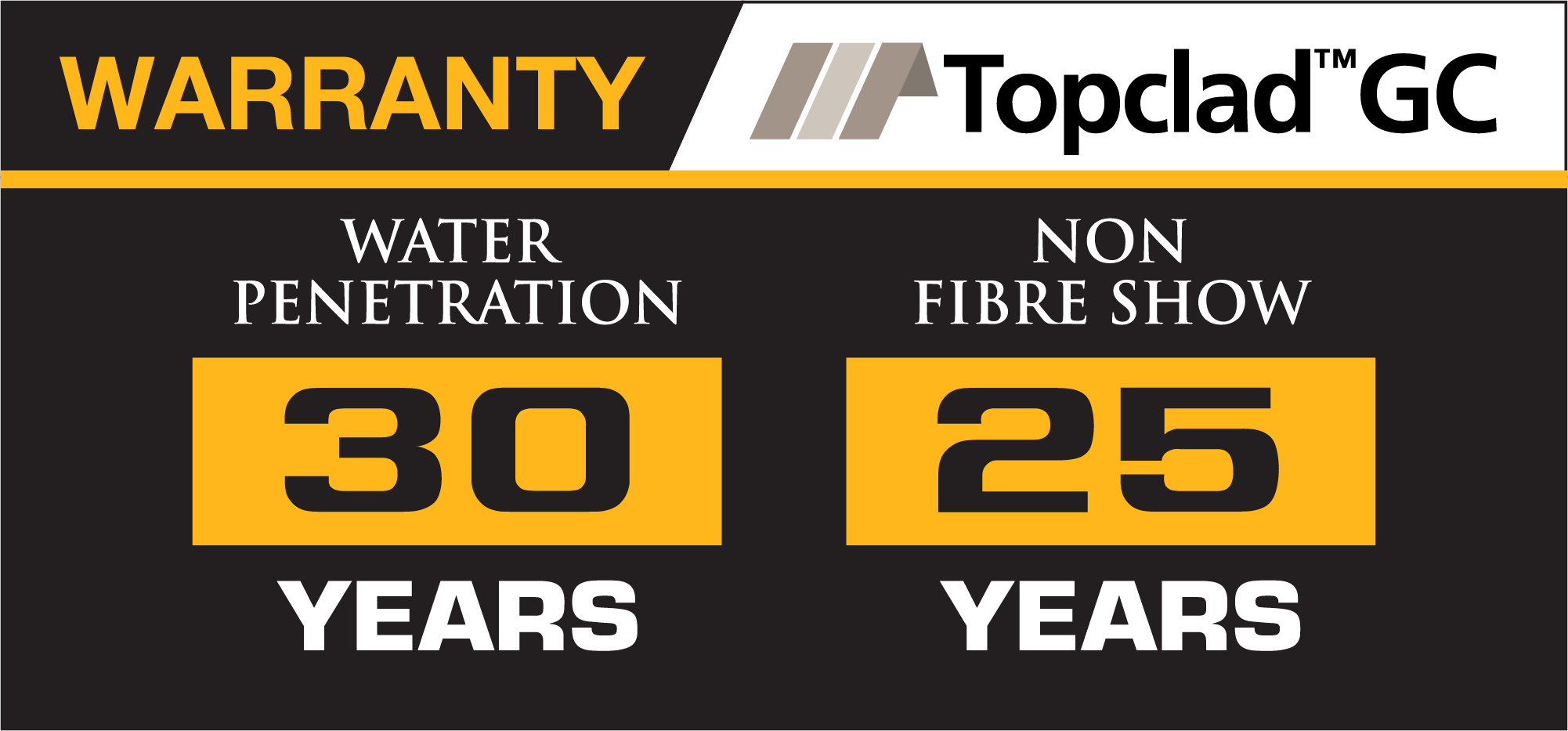

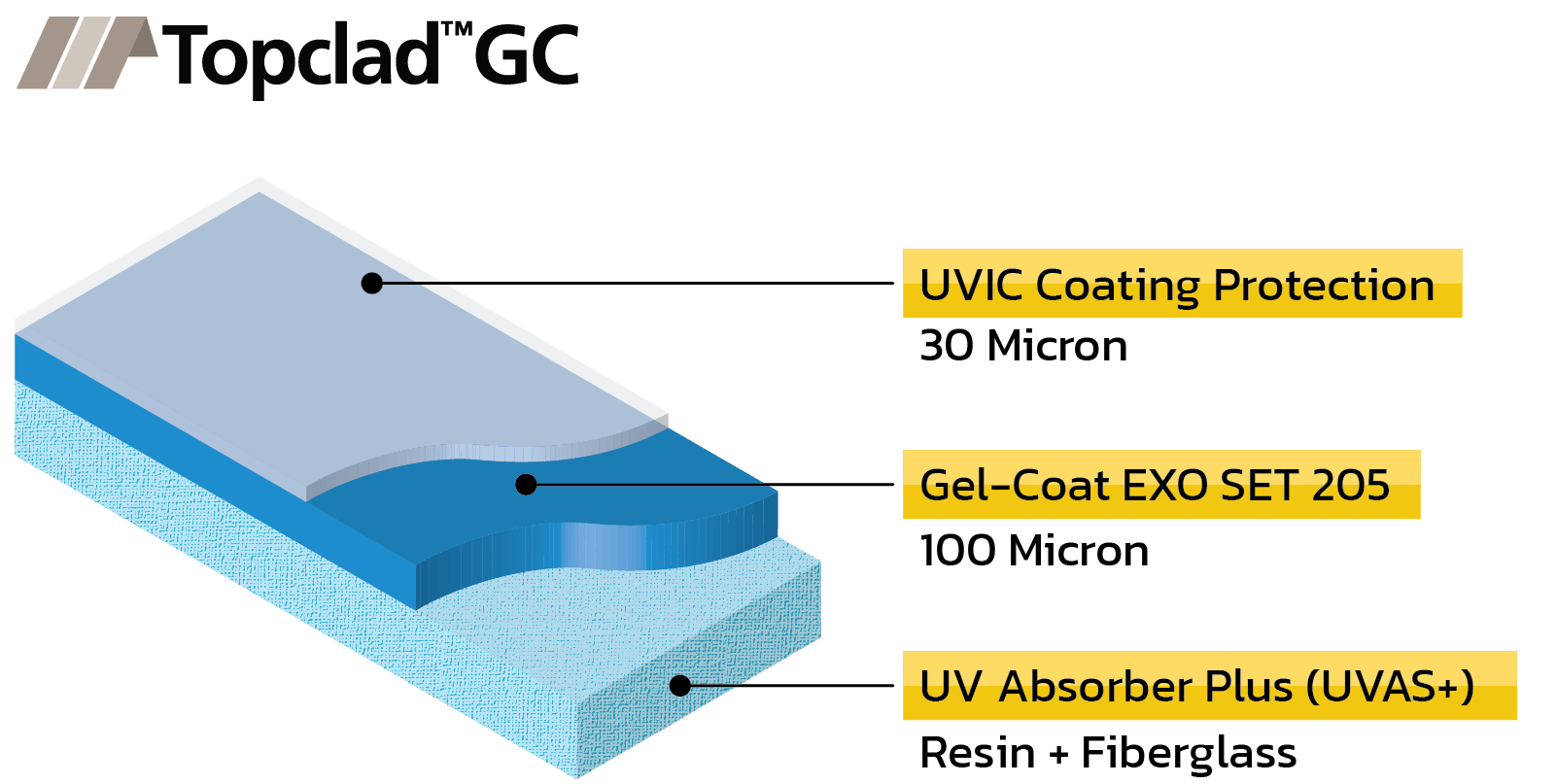

Topclad® GC

HEAVY DUTY CORROSION RESISTANT, SOLID-COLOURED ROOFING AND CLADDING SYSTEM

In highly corrosive industrial sites and areas of high salt and contamination, any paint coatings on roofing and cladding such as aluminium and steel may not perform as expected. To address these concerns, we manufacture a unique solid-coloured heavy duty roofing and cladding material utilising advanced FRP technology to formulate a corrosive resistant cladding system for use as an innovative replacement for traditional materials. This is our Topglass Topclad GC.

Key Benefits

– The surface coatings and substrate used in the manufacture of Topglass GC Topclad have been designed specifically to withstand most corrosive atmospheres.

– Has on known reaction with any construction materials and unaffected by solvents including hydrocarbons and has ability in resisting to most acids and alkalis.

– Topglass GC Topclad is solid-coloured to match modern roof colurs (Subject to pigment availability) this is achieved by applying a 100 micron* gel-coat layer to the FRP sheeting substrate.

– Advanced technology associated with the Inno-cons Gel-coat manufacturing process allows different solid colour pigmentation to be applied to each side of the sheet, particularly important where the underside of the sheet is not covered by a membrane.

– Abailable to match a wide range of roof profiles including flat sheet.

– Lightweight cladding for easy handing and installation.

– Reduces solar heat transmission.

Applications

– Fertilizers buildings

– Power plants

– Petroleum and Chemical Plants

– Galvanizing Plants

– Acid Plants and Smelters

– Effluent tank cladding;

– Extreme marine environments;

– Buildings in geothermal areas

Topglass Laboratory

1. Barcol Hardness (Barcol Impressor Model no.GYZJ.934)

2. Exposure Ultraviolet lamps M/C (Compile AS/NZS 2433)

3. Spectrophotometer (Model no. CM-3600A for measurement L,A,B)

4. Diffuse Light Tranmission M/C (AS/NZS 4257.4)

5. Impact Resistant M/C (Compile AS/NZS 4257.6)

6. QUV Accelerated Weathering Chamber UVB313 (ASTM G53)

7. Microscope Camera

Spacification

Raw Material

Manufacture a unique solid-coloured heavy duty roofing and cladding material utilising advance FRP technology Vinyl Ester Resin produced with a special process from New Zealand, with a solid color, which produced will be strong and resistant to chemical corrosion

Top Coating

EXO-SET 205 100 micron gel-coated surface which is reactive thermo-set to provide a high gloss surface.

Fiber Glass

Antistatic high quality glass fibre rovings to give maximum strength during the curing and bonding process.

Bottom Coating

Release film.

Production Process

CHP Technology Cumean Hydro Peroxide Activater.

Thickness / Weight

The standard weight for Topclad GC is 2800 GSM (1.9 mm)

Other weights up to 3660 GSM (2.5 mm) are available subject to minimum order.

Color

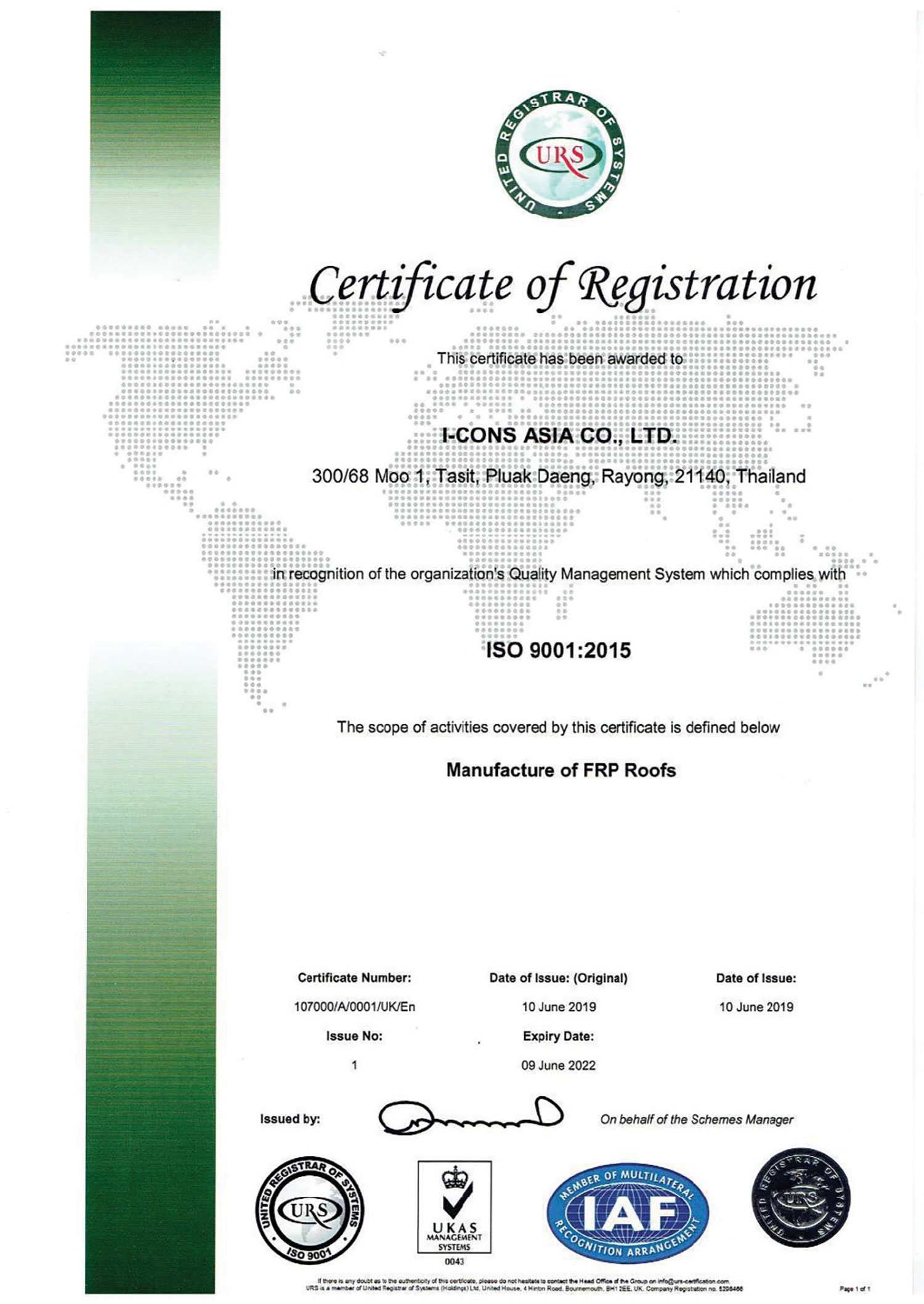

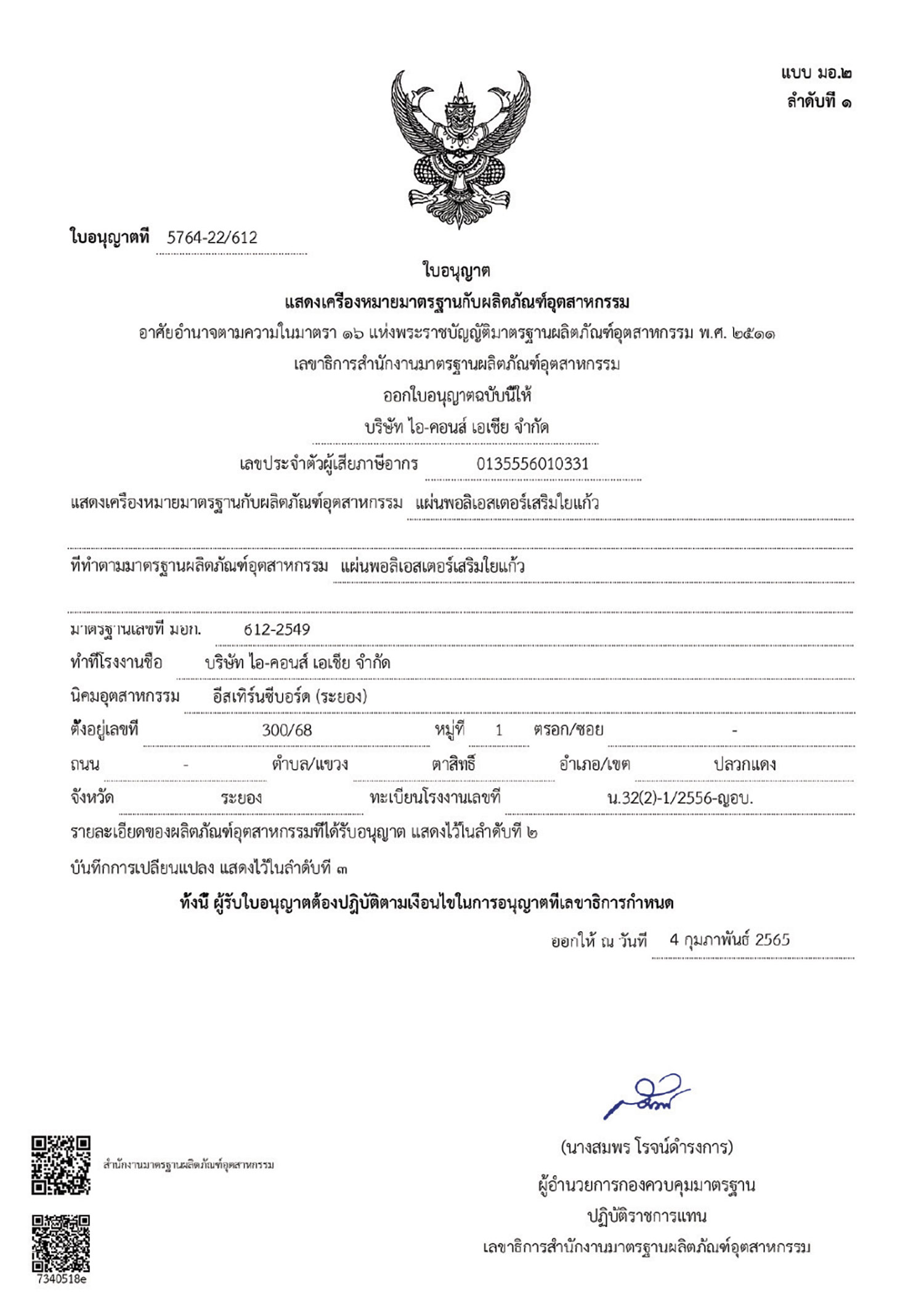

Standards & Certifications

ISO 9001 : 2015

TIS 612 – 2549

AS/NZS 4256.3 : 2006

– AS/NZS 4256.3 : 2006 Client BMP NO.535535 Plastic Roof and Wall Cladding Materials ID : 4115 จากประเทศนิวซีแลนด์

– มอก.612-2549 มาตรฐานอุตสาหกรรมจากกระทรวงอุตสาหกรรมประเทศไทย

– ISO 9001:2015 จาก URS